Choice of Solutions

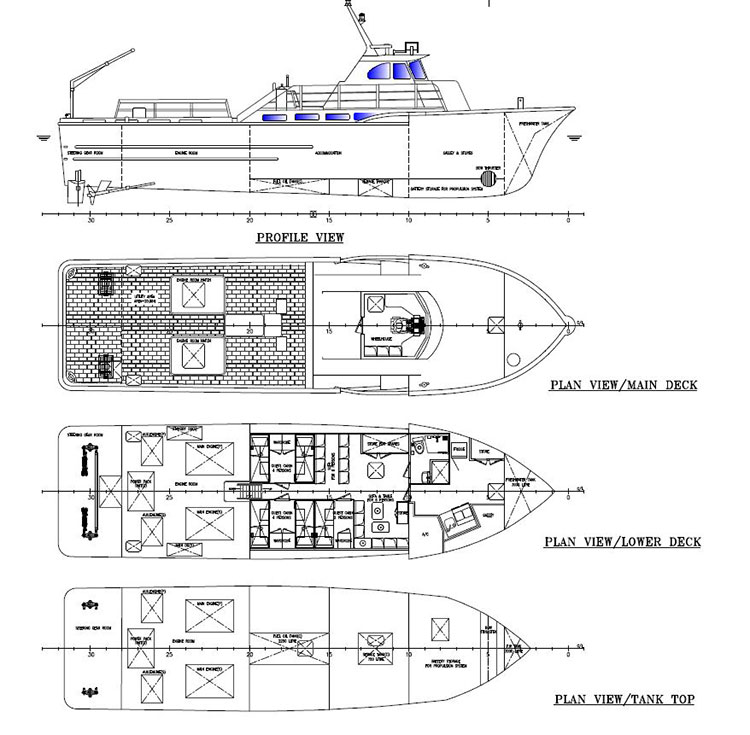

Ocean Tech Solutions heavily involved in naval architecture services from concept design, conversion, small craft and barges.

Our core activities such as;

With the in-house capability to convert/modify the existing vessel to its specifics needs with design and analysis full ship structure to international classification society standards for both steel and aluminium hull.

Our core activities such as;

CFD stands for Computational Fluid Dynamics, which is a simulation technique used in engineering to analyze how fluids (such as air or water) interact with objects like ships, submarines, or offshore structures. It helps in understanding factors like fluid flow patterns, pressure distribution, and forces acting on the object.

Sea trials, on the other hand, are physical tests conducted on a vessel in real-world conditions, typically in an actual body of water like the ocean. These trials are essential to evaluate the performance, stability, and safety of a ship or maritime equipment.

When Ocean Tech Solutions offers CFD/sea trials services, it means they provide a combination of computational simulations (CFD) and real-world testing (sea trials) to assess and optimize the design, performance, and efficiency of marine structures and equipment. This integrated approach can help ensure that maritime projects meet safety and performance standards before they are deployed in actual ocean environments.

Tank sounding calculation report the process typically involves manually measuring the liquid levels in tanks using sounding rods or electronic sensors. These measurements are recorded and used to calculate the volume or weight of the liquid in each tank. Reports are then generated to document these calculations, often including details like tank location, liquid type (such as fuel, water, or cargo) stored in the ship's tanks, level measurements, and the resulting volume or weight.

Ocean Tech Solutions provides a Trim and Stability Booklet service, which is essential for ships and vessels. This service involves the preparation and maintenance of a booklet that contains vital information about a vessel's trim (the balance of the ship) and stability (its ability to return to an upright position after being tilted). Here's an explanation:

Hull stress represents a significant factor contributing to irreversible damage in merchant marines. The accumulation of fatigue within vessels can result in local hull cracks, which may lead to catastrophic structural failures, posing a grave risk to life. One of the key challenges has been the lack of real-time hull/structure load data accessible from the bridge. To mitigate such damage, a solution is needed to collect and readily provide this information to navigators. In response to this need, the IMO and leading Classification Societies have recommended the adoption of Hull Stress Monitoring Systems to reduce the occurrence of such failures.

Hull stress monitoring system commonly used in maritime applications. This system uses various sensors and analysis methods to measure and assess stress on a ship's hull. The sensors, including strain sensors, accelerometer units, and bow pressure transducers, capture data related to static, dynamic, slowchanging, and temperature components of stress. This data is then sent to a central unit on the bridge for further analysis, data logging.

Fuel oil sampling is performed to monitor and verify the quality of the fuel oil onboard ships. It helps ensure compliance with international regulations and standards.